+ Conformance, Extensiblity & Stretch

Add the Micrex Process to your products to give them machine direction extensibility.

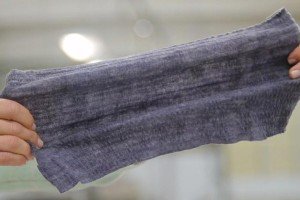

+ Softness, Drape & Hand

Enhance softness by adding the Micrex Process, a critical property whenever a substrate comes in contact with the human body.

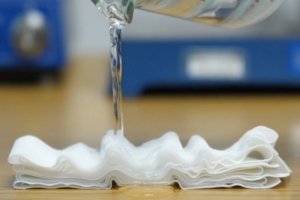

+ Bulk

Micrex can increase bulk in your sheet materials, allowing for improved cushioning, airflow, drainage, insulation, and absorbency, among other attributes.

+ Absorbency

Alter absorbent efficiency, speed of absorption, and total absorbency with The Micrex Process.

+ Decorative Effects

Add the crepe look to your nonwoven or textile: a high-fashion effect executed with the Micrex/Microcreper.

+ 4D – Pre-Shrinking

Add the Micrex Process to your sheet materials to give them the properties of 4D – dynamic change over time.

Materials Processed

Nonwovens

The Micrex Process has been used since the infancy of the nonwovens industry to enhance nonwoven substrates.

Films

Microcreping can add properties to your film products, such as an increase in machine direction stretch of up to 300% (25% is typical), or an increase of up to 20 times the original film thickness.

Composite Structures

Composites provide a whole new way to take advantage of the Micrex Process and the properties it can add to your products.

Paper

Micrex provides a softer, more environmentally friendly crepe than traditional wet creping.

Textiles

The crepe look is also a high fashion look executed by The Micrex Process on textiles.

How We Work

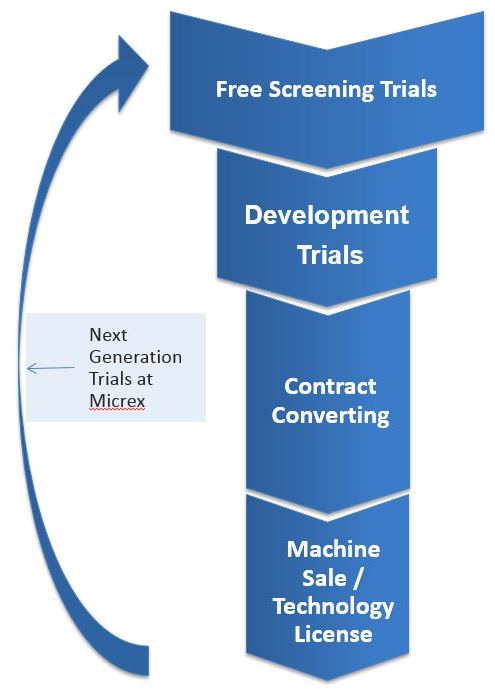

The Micrex Process has a minimum of 27 different points of adjustment. Each of these “points” has from two to almost infinite levels of adjustment, allowing for potentially millions of different sets of process settings. In addition to these machine settings, the recipe of the incoming material is critical to the performance of the process.

As there is no reliable predictive model for how a particular substrate will process on a Micrex/Microcreper, Micrex technology is applied using an empirical model based on trials. We have three lab scale machines in our production facility, on which we can produce all nine configurations of Micrex/Microcreper. This allows us to efficiently test your product under a wide range of conditions to quickly arrive at a go/no go gate toward further development.

As there is no reliable predictive model for how a particular substrate will process on a Micrex/Microcreper, Micrex technology is applied using an empirical model based on trials. We have three lab scale machines in our production facility, on which we can produce all nine configurations of Micrex/Microcreper. This allows us to efficiently test your product under a wide range of conditions to quickly arrive at a go/no go gate toward further development.

Based on the success of these initial “screening trials” for your product, we can seamlessly move through developmental and then production trials. Our extensive know-how allows us to optimize the final product to fit with your objectives.

Very often we are able to suggest modifications to the base substrate to not only improve performance on the Micrex/Microcreper, but also to yield system-wide lower costs.

A close working relationship with our customers is critical to success. Successful firms have learned that even when one round of product development has been completed, the key to continued success is to integrate Micrex in subsequent generations of products.

Almost without exception — no company has been able to successfully innovate new Microcreped products on their own production equipment.