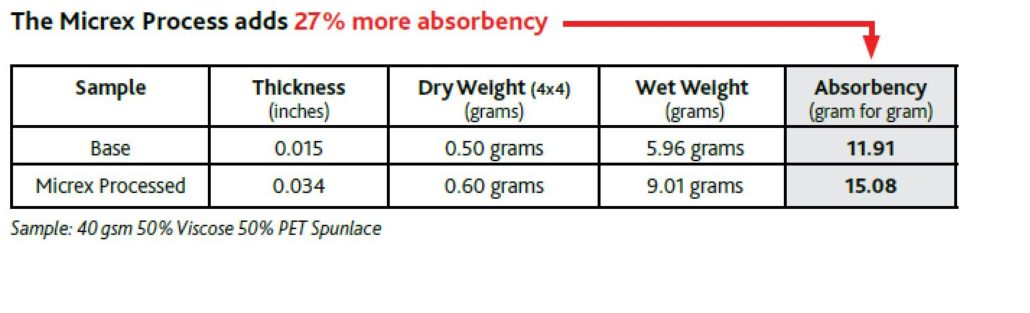

The Micrex Process can improve the absorbency of your sheet materials.

Enhance absorbency to Increase Performance and Lower Cost

Enhance absorbency to Increase Performance and Lower Cost

More internal volume translates into more absorbency. In fact, an equal weight of spunlace will absorb and retain over 20% more fluid. The result: a significant increase in performance and/or cost savings.

Absorbency can also be a by-product of other Micrex properties such as softness, drape and bulk.

Traditional Measures of Absorbency

• Speed of Absorption

The amount of liquid a given sample can absorb in a (short) period of time.

Example: a diaper needs to quickly absorb an insult. The test would likely end before the sample was completely saturated.

• Absorbent Capacity

Like speed of absorption, the amount of liquid absorbed by a given mass, but in a longer period of time. This sample may reach initial saturation.

Speed of absorption and absorbent capacity are the standard test methods used to evaluate substrate performance. At Micrex, as we alter material properties to improve absorbency, we use further measures to evaluate product performance:

Enhanced Measures of Absorbency

• Absorbency Time

The amount of liquid that can be absorbed by a sample so that it is completely saturated. Similar to speed of absorption, but not limited in time. Example: this measure would be important for a bandage that is intended for long use.

• Total Absorbency

This measure is about maximizing the amount of fluid absorbed in a given amount of time. As such, the container volume is kept the same between samples, but the mass can vary. Goal is to reach the maximum density possible for the absorbent material.

Example: a tampon has an optimal density, in which total absorbency is maximized. Increasing or decreasing the amount of material will result in decreased absorbency.

• Absorbent Efficiency

Volume is constant for this measurement, but amount of material will be varied to maximize absorption per unit mass of the sample.

Example: a paper towel – a product that needs to absorb as much as possible relative to the amount of material used.

By combining different process settings and fiber blends, Micrex can enhance absorbency in each of these measures.

Micrex technology enables a new measure of absorbency:

Micrex would like to introduce a new measure of absorbency.

• Dynamic Absorbency

Most materials shrink when wet. Microcreped materials have been “pre-shrunk”, so they can expand when wet, exerting force to absorb even more liquid.

Play video to see Dynamic Absorbency in action.