4D Substrates Now

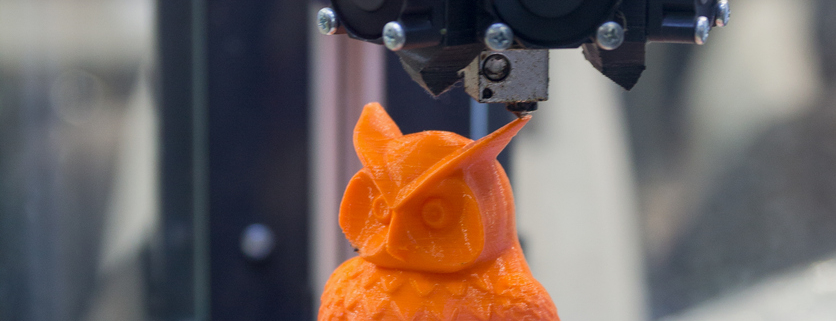

4D Printing is a combination of 3D printing and a time change element that provides the fourth dimension — hence a 4D substrate is one that will by design change form over time.

Smart fabrics and 4D printing were identified by Gartner as technologies way up on their hype cycle.

We tend to agree with their assessment.

However, there are useful lessons from additive manufacturing for those of us in the roll goods industry — even if 3D (let alone 4D) roll goods are not in the immediate future.

- We should look at how our products are made from a fresh perspective. Many roll goods are constructed using technology that is decades old. Additive manufacturing teaches us that there may be unforeseen ways to construct a better product.

- Rather than focusing on what our products are made of (e.g., polyester, viscose) we should be focusing on what product properties (extensibility, absorbency) we are trying to achieve.

There is no need to wait for 3D printing to mature to the point that we can make 4D products. The technology for 4D fabrics is readily available now by combining existing technology in new ways.