The Micrex Process: No Waste – Environmentally Friendly – High Operating Speed

The Micrex Process: No Waste – Environmentally Friendly – High Operating Speed

The original Micrex/Microcreper was created with the goal of being a better way to crepe paper. The inventors never conceived that the technology would find much broader application processing textiles, films and the yet to be developed family of substrates known today as nonwovens.

The technology is best viewed as a solution where traditional wet creping is not applicable.

Benefits include:

- Dry process: no waste; no environmental concerns

- Operating speeds of 200+ meters per minute on some substrates

- No steam or adhesive used in processing (eliminating the wetting and drying of the paper)

- Can process papers that cannot withstand creping due to low wet strength

- Result: Much softer crepe

Paper makers and converters worldwide have utilized the benefits of crepe paper to enhance their products. Historically there have been two ways to add stretch and extensibility to these substrates — traditional wet creping and the Clupak® process. Unfortunately, the use of these technologies has been confined to a limited range of materials. Further high energy costs and low operating speeds have limited the number of applications of these methods.

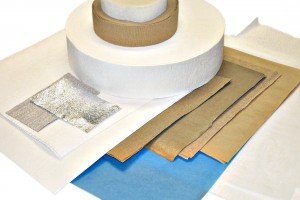

Manufacturers can now use the Micrex/Microcreper to enhance the performance of their paper and engineered cellulosic substrates.

Technical Note 119 Paper – Wet vs Dry Process

Clupak is a registered trademark of Clupak Inc