The Micrex Process can add bulk to your sheet materials. Increased bulk allows for improved cushioning, airflow, drainage, insulation, and absorbency, among other attributes.

More volume translates into more absorbency. In fact, an equal weight of spunlace will absorb and retain over 20% more fluid. The result: a significant increase in performance and/or cost savings.

Bulk is not only about absorbency. In insulation, bulk creates air trapping – reducing both thermal conductivity and noise. Bulk also leads to increased surface area — important in filter media.

How Bulk Enhances Your Product

Illustrated are 8 sheets of unprocessed and processed spunlace. The processed webs have 3 times the caliper of the unprocessed. Comparing two stacks of wipes of the same weight, the Micrex Processed wipes have over 15% more volume when wet (under certain process conditions).

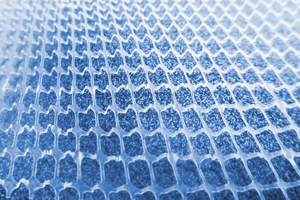

+ Bulk = Adding Air and Space

Bulk is also about air and space. Space that can be used for airflow or even trapping, holding and gripping.

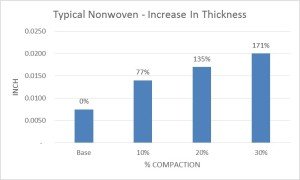

Even at low levels of compaction, it is possible to dramatically increase bulk.

Increased bulk is defined as a measurable rise in the thickness of a treated product, as well as a rise in basis weight per unit area. The increase in basis weight is directly proportional to the amount of compaction present in the substrate. Note that the increase in thickness can be much greater than the increase in basis weight.

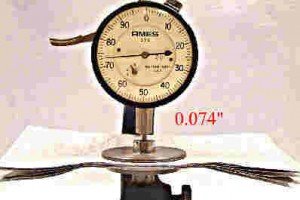

The Micrex test method for measuring thickness of Microcreped material requires little equipment.

For the product designer, this disproportionate increase in thickness offers exciting opportunities for product enhancement. For example: in specific web structures, this can translate into improved absorption in both rate and volume of liquid pick-up, as well as retention.

For the product designer, this disproportionate increase in thickness offers exciting opportunities for product enhancement. For example: in specific web structures, this can translate into improved absorption in both rate and volume of liquid pick-up, as well as retention.