At Micrex, we are introducing a new way to work with materials that up to now have been impossible to process in sheet form. Composite structures allow product designers to reap the benefits of Micrex/Microcreping, adding features such as extensibility, bulk, and absorbency in sheet material.

At Micrex, we are introducing a new way to work with materials that up to now have been impossible to process in sheet form. Composite structures allow product designers to reap the benefits of Micrex/Microcreping, adding features such as extensibility, bulk, and absorbency in sheet material.

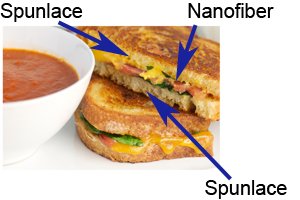

Many things will not Microcrepe. Think about a sandwich: Clearly you wouldn’t run an actual sandwich through any processing equipment. At Micrex, by “sandwiching” the material that is difficult to process between two layers of a sheet material which processes well, the “ham and cheese” material can be enhanced with the benefits of Microcreping.

Very often Microcreping is only beneficial to a small part of a composite structure. Our solution is to combine one layer of creped substrate with one or more layers of uncreped substrate to create new structures which have not been produced before.

Product Concepts Using Composites

Wet Wipe

Soft on one side, scrubbing surface on the other side

Diaper

A new kind of ADL which transports the insult without gel blocking

Construction Sheets

Improve insulation, conformability and acoustics of any construction sheet

Automobiles

Decorative layer or enhanced internal structure for automobile headliner

Extension limiting of an extensible film

Improve insulation, conformability and acoustics of any construction sheet

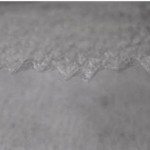

Filter Media

Bulked carrier for a nanofiber layer