The Micrex/Microcreper is a dry mechanical compressive-treatment (creping) process that conceptually is similar to a stuffer-box — but across the entire width of the web.

The video above gives a broad overview of how The Micrex Process works. For a more technical representation of the development, see one of our early patents.

Configurations:

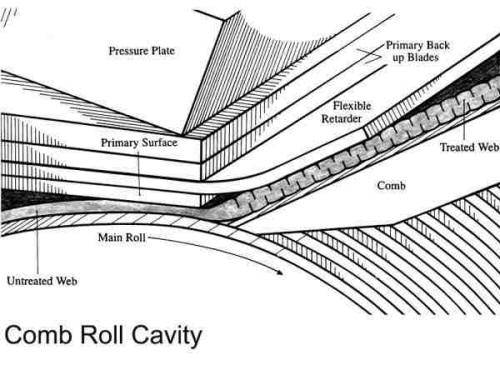

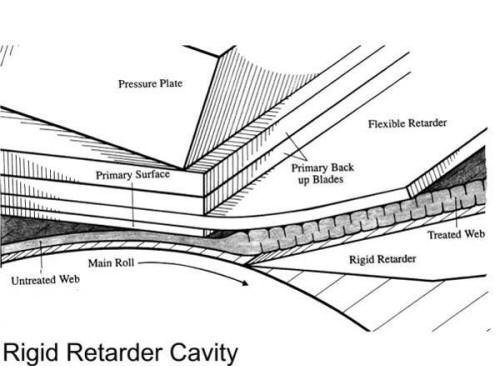

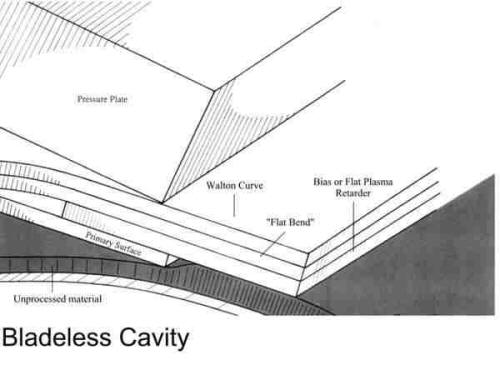

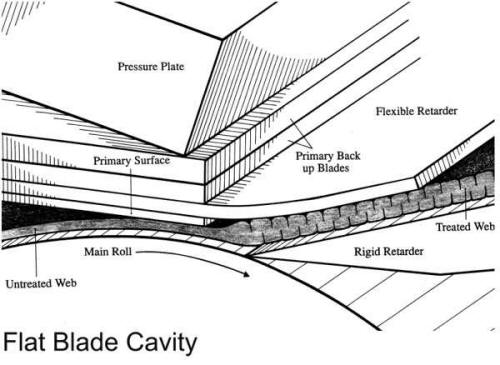

The Micrex/Microcreper has five base configurations: Comb Roll, Rigid Retarder, Bladeless, Flat Blade and Two Roll. In addition, five advanced configurations are available in-plant to our contract converting customers.

The Comb Roll configuration is widely used to soften hydro-entangled nonwovens and to crepe high basis weight substrates.

The Rigid Retarder configuration (the original Micrex configuration) can soften wet laid products and crepe paper, as well as process a wide range of nonwovens.

The Bladeless configuration can soften lightweight nonwovens, bulk gauze, and a wide range of pre-shrinking applications. Designed to compact less structured materials, the bladeless cavity is used in a variety of applications that cannot withstand the forces of the Rigid Retarder cavity.

The Bladeless configuration can soften lightweight nonwovens, bulk gauze, and a wide range of pre-shrinking applications. Designed to compact less structured materials, the bladeless cavity is used in a variety of applications that cannot withstand the forces of the Rigid Retarder cavity.

The Micrex/Microcreper equipped with a Flat Blade cavity is designed to give the textile finisher maximum flexibility to respond to a competitive style-driven marketplace.

A poly/cotton material can be made into a whole series of rich decorative styles. Many decorative styles are possible; plisse, crepe, and seersucker can all be created on the same basic material within minutes.

The process utilizes a specially formed blade, which selectively compacts the fabric. New styles can be configured by the operator using scissors, simply by cutting patterns in a steel blade. The spacing is limitless and is solely up to the finisher. The Micrex/Microcreper is able to impart a myriad of patterns with a relatively short changeover time, typically 2-3 minutes. In one case of a shower curtain manufacturer, the customer specified a 5 inch wide “pucker” with a 1/4 inch compacted width.

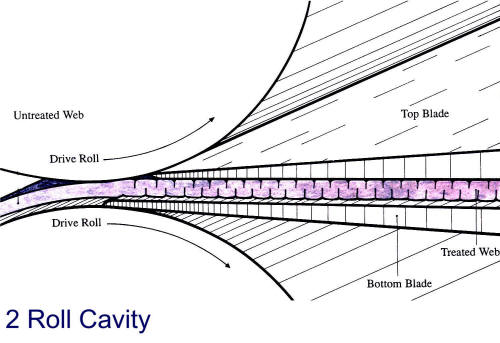

The Two Roll cavity — utilizing two drive rolls and two retarding blades, is at the core of the Micrex/Mark II technology.

Designed to minimize damaging heat at high speed, this system processes low melting point substrates such as polypropylene or polyethylene.

Micrex/Microcrepers (in basic configurations) are available in widths ranging from 42″ (1067 mm) to 124″ (3150 mm). Microcreper systems are designed to be operated by a single operator. A PLC controlled digital drive system runs at speeds up to 300 meters per minute, depending upon substrate conditions. Micrex has complete turnkey systems available, including all ancillary equipment. The Microcreper can also be purchased individually, along with a custom selection of ancillaries.

Micrex/Microcrepers (in basic configurations) are available in widths ranging from 42″ (1067 mm) to 124″ (3150 mm). Microcreper systems are designed to be operated by a single operator. A PLC controlled digital drive system runs at speeds up to 300 meters per minute, depending upon substrate conditions. Micrex has complete turnkey systems available, including all ancillary equipment. The Microcreper can also be purchased individually, along with a custom selection of ancillaries.

![]() Representative Description of the Rigid Retarder Configuration

Representative Description of the Rigid Retarder Configuration